How it works

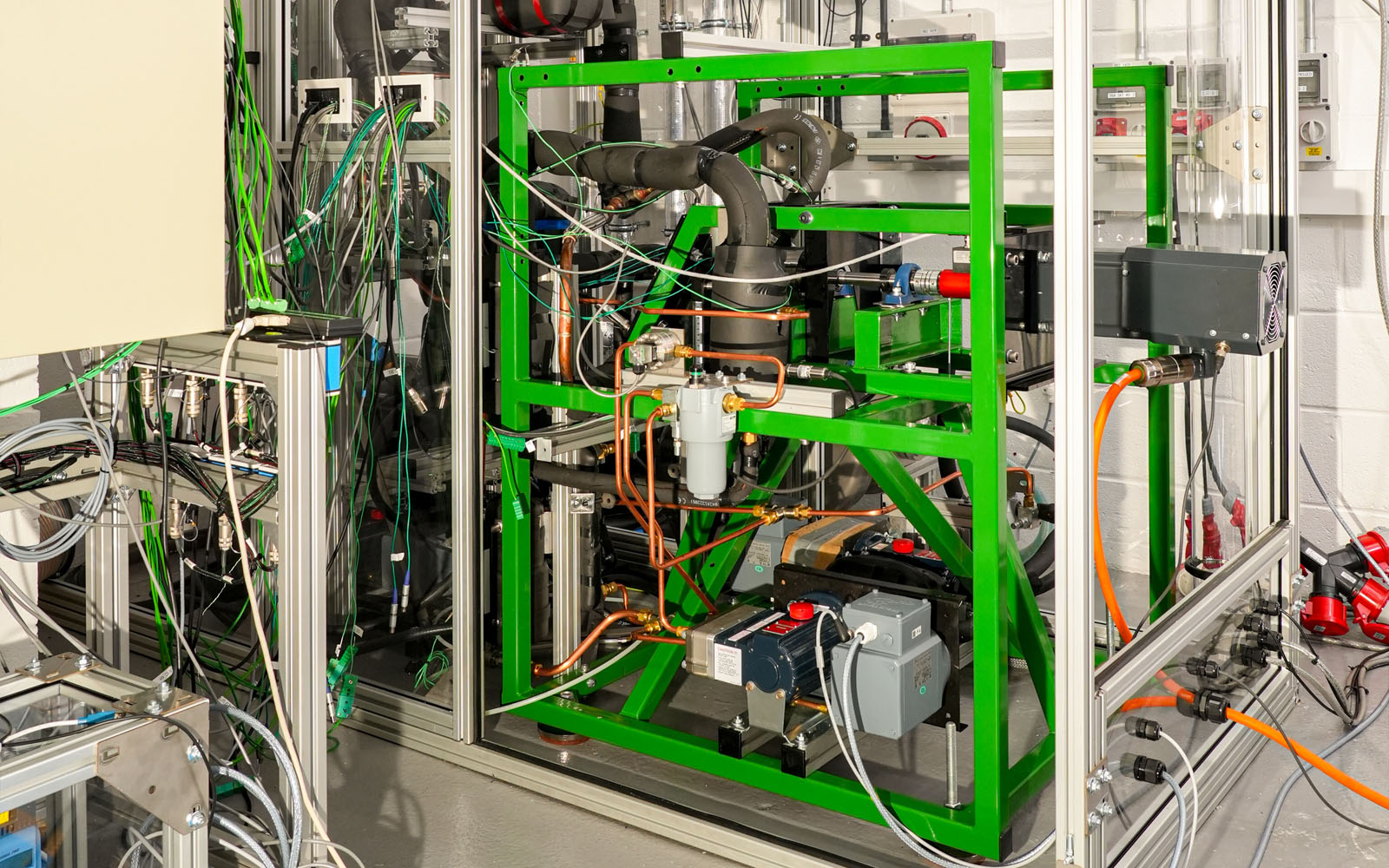

Heat is absorbed from a thermal energy source (air, water, ground, waste) through the heat input heat exchanger causing the system’s internal fluid flow to boil into a low-pressure gas, at which point it then travels to the compressor.

Air

Water

Ground

Waste Heat

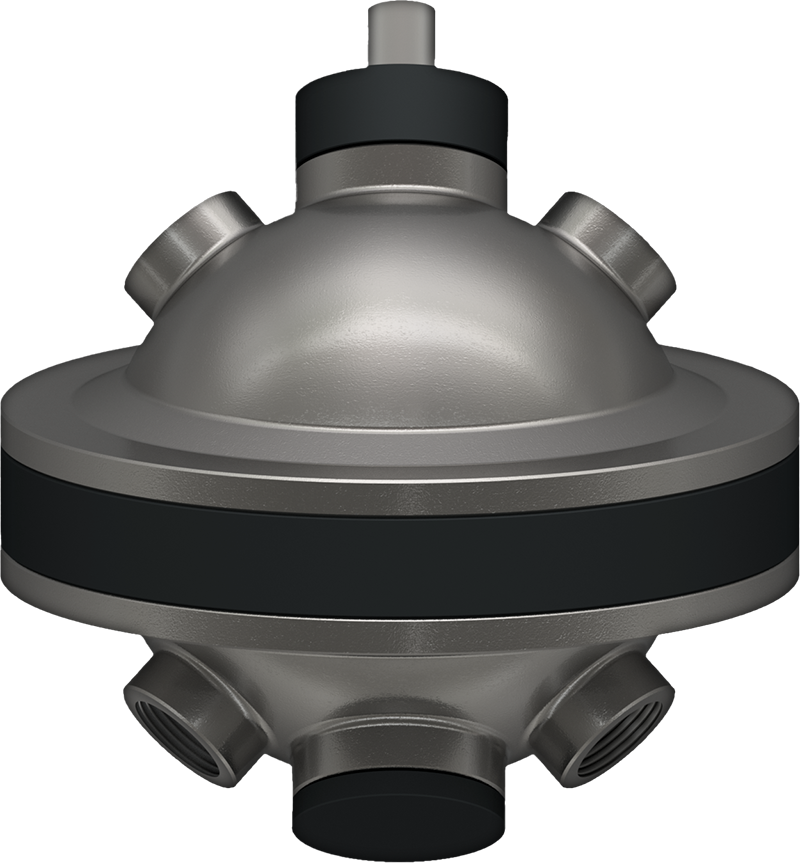

The low-pressure gas from the heat input exchanger enters the highly efficient FeTu compressor, where our unique mechanical compression process increases its energy, turning it into a hot, high-pressure gas which then passes to the heat output exchanger.

Electrical Power InputFollowing the compression process, the hot gas enters the heat output exchanger, as does the counterflow material requiring heating. The hot gaseous fluid within the heat pump circuit then condenses and in the process transfers heat to the external fluid media, thereby increasing its entropy and enthalpy, ultimately raising its temperature.

Air

Water

Steam

Process Heat

Within the heat pump circuit, the cooled liquid from the condenser enters an expansion valve where it expands from a high-pressure liquid to a lower-pressure 2-phase (saturated gas) fluid, significantly dropping in temperature due to a Joule-Thomson effect.